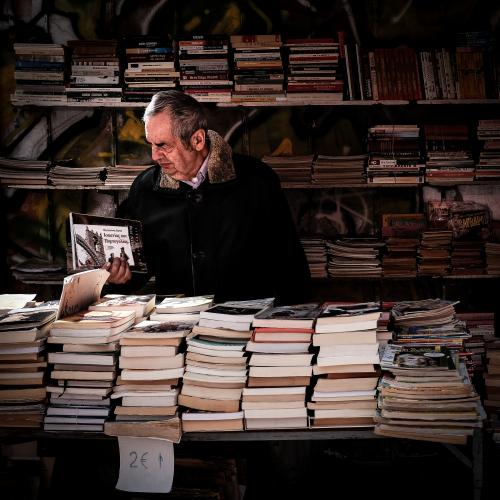

Paul Bunyan. Pecos Bill. Johnny Appleseed. These American myths have stood the test of time, and are still retold across kindergartens and elementary schools nationwide.

While they are stories of strength, might, courage, and goodwill, they are not entirely factual. By not entirely factual, I mean they aren’t really true at all (although I think Johnny Appleseed may have been based on a real person. I’ll Wikipedia that and get back to you).

These myths are amusing and when we hear them today, they create a nostalgic sense of joy. But again, they are not true.

Equivocally, there are certain myths in service truck industry that are fun to believe, but much like Paul Bunyan and his blue ox, they are downright false, and unlike these classic American tall tales, they can hurt your business’s bottom line.

1. Most Service Trucks Have A Lifespan of 6 Years With Heavy Use

The old 6-year myth is one of our favorites. Although we cannot trace the exact origins of this falsehood, we imagine that it started to bubble up in the 80’s and 90’s, when steel service bodies were all the rage.

Consequently, it was a common adage to suggest upgrading or severely servicing a truck for upgrades after the 6-year mark. It is the equivalent of the “change your oil every 3,000 miles” advice that was conventional before the advent of synthetic oil.

New age service trucks drastically outlive those of the past with the implementation of more modern materials, such as aluminum and carbon fiber that significantly reduce the amount of wear that the truck and chassis were subjected to previously.

2. Steel Is More Durable And Longer-lasting Than Aluminum

To piggy-back off the previous myth, there is a dirty rumor floating around that even in 2018, steel is a more durable and longer-lasting material than aluminum for service truck bodies.

Aluminum technology has progressed through the times at a rapid pace. In this day and age, aluminum alloys are being used in applications once designated only for steel. Through extensive research, aluminum alloys can now provide the same (if not better) durability in heavy-duty use as steel.

Not only can aluminum provide comparable durability, the longevity of the material eclipses that of steel because of its resistance to rust and subsequent erosion.

Those still pledging allegiance to steel service truck bodies will be shocked to find that their conventional wisdom is now a myth of a once true notion.

3. Crane Choice For A Service Truck Body Is A Preference

No. No it isn’t. You cannot justify using a telescoping crane on a service truck body designed for liquified petroleum tank transport. In that same sentence, you cannot justify tossing a knuckle boom crane on a mobile mechanics truck (mainly because that makes about zero sense).

I hate to sound like a broken record, but this is 2018. The efficiency lost from logging professionals still using telescoping cranes is enormous, not to mention the safety issues.

At this juncture in service truck body history, there is enough data available to specify what type of crane you should equip your truck with. Increasing efficiency and mitigating safety risks should be top priorities when selecting a crane.

4. All Service Trucks Have The Same Features

If you buy mass-produced, cheaply made, cookie cutter trucks from the same manufacturer, then yes this is a fact. If you look peripherally at the market place, this is as much of a myth as a lie.

There are now manufacturers that are taking into account industry-specific needs, and crafting service truck bodies to address the unique issues of professionals in each specific industry. The result is a marketplace where customers come first, and the manufactures of these service truck bodies constantly adapting to accommodate the very unique jobs that the trucks are designed for.

A mobile mechanic should have an industry-specific toolbox that differs from an electrical contractor. Their needs are different.

Smart manufacturers recognize this and create service trucks to best suit the needs of their customers, rather than mass producing run-of-the-mill bodies that poorly accommodate every industry.

5. Industry-specific, Customized Service Trucks Are Far More Costly

Customized naturally means more expensive right? Not in the work truck world. If we are discussing the upfront cost of purchase, there may be a minor price hike, but when viewing a service truck as an investment, customization is almost always a money-saving option.

Considering customized trucks are built for ease of work in a specific industry, they will almost always save the owner time. Customized trucks are only fractionally more expensive (if at all) at the purchase time, and customized service trucks are built to accommodate the terrain and use of the contractor or professional in their line of work.

6. The More Expensive The Truck, The Higher The Quality

The more expensive the truck, the better the quality should instead read, "The more expensive the truck, the bigger the brand.”

When purchasing a service truck body, people often look to big brands that produce clunky, one-size-fits-all vehicles and pay a premium for the branding. While the buyer may suffer from brand loyalty, they are ultimately hurting themselves by paying more for less functionality.

Conclusion

Keeping these myths in mind, you can prepare for your next purchase with a fresh, new perspective on how to get the best deal possible on a service truck that makes sense for you and your business.