JOMAC crafts customized service trucks based on the unique needs of each individual customer. Built to spec, each utility truck body is created with precision, bringing your blueprint of the perfect work truck to life. We guarantee a service truck body optimized to meet the demands of your work and exceed your expectations of what a service truck can be.

All service truck bodies and cranes are carefully hand-crafted at our Carrollton, OH facility. We do not cut corners with cookie-cutter configurations. JOMAC dedicates the time and effort required to create one-of-a-kind service trucks and cranes, made in the heart of America. Our custom truck body designs and truck-mounted cranes are forged by the hands of our skilled craftsmen. No assembly lines necessary.

Aluminum is a durable and light weight solution for the unnecessarily heavy steel service trucks of years past. The forward-thinking engineers at JOMAC build truck bodies using exclusively 6000 series, military grade aluminum. Each aluminum truck body is guaranteed to be rust-free for life. Seriously.

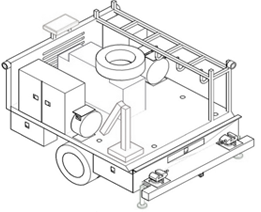

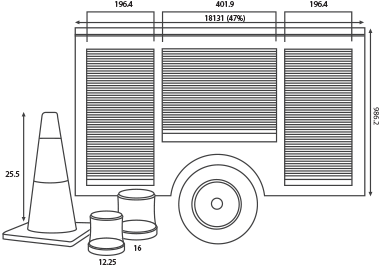

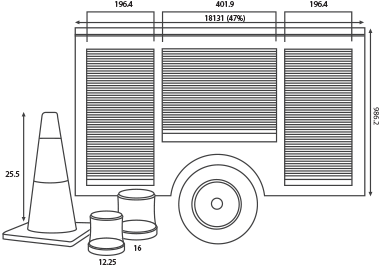

Service Truck Bodies

When you come to JOMAC with highly specific needs for your truck body, we collaborate and hand build custom truck bodies designed precisely for a truck's or fleet's intended use.

Learn More

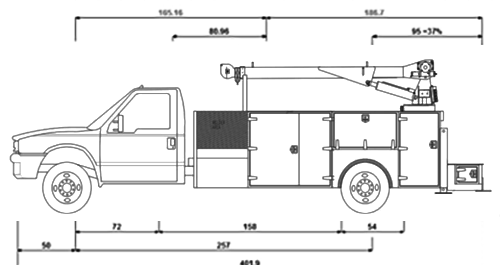

Mobile Cranes

JOMAC manufactures Knuckle Boom (articulating) and Telescoping Cranes to be mounted to our utility bodies. We have a variety of strategic mounting options so your crane will achieve its maximum usage.

Learn More

Accessories

JOMAC understands that all of your tools and necessities come in various shapes and sizes.

Functionality is of the utmost importance, and JOMAC accessories ensure the shape and size of your need is met.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More